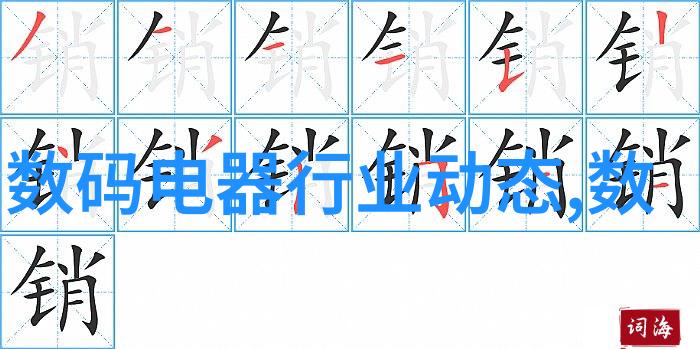

丝网波纹填料a组填料图片展现之美250AX 500BX 700CY选项12丝6精细打造

金属丝网波纹填料,以其卓越的性能和广泛的应用,成为了全球范围内被广泛采用的高效填料。这种填料由众多平行且直列排列的金属波纹网片构成,形成了一种圆盘状的结构。它拥有显著的大比表面积、孔隙率以及轻量级特点;其气相通路倾斜角度小而有规律性,压降也相应降低;此外,它在径向扩散方面表现出良好的效果,并能够实现充分的气体接触。

金属丝网波纹填料不仅因其独特优势而备受青睐,而且在性能参数上也有着明确区别:

型号:250AX、500BX及700CY,每个型号都具有一定的峰高、高比表面积、高堆积重度以及对倾斜角度和空隙率等方面的一致性。

比表面积m2/m3:通过精细计算得出,这些值对于不同型号来说是关键指标。

堆积重度Kg/m3:反映了每单位体积所包含物质的质量,是衡量材料密实程度的一个重要指标。

倾斜角度与空隙率m3/m3:这些数据决定了气体流动路径,以及空间中可利用容积大小。

每板压力降Pa/n & HETP /mm:这两个参数直接影响到填料在实际使用中的效能和经济性。

理论板数m^-1 & F因子m/s(Kg/m^30.5):

理论板数代表了理想状态下的最大通量潜力,而F因子则反映了该类型材料在处理过程中的阻力系数。

这些具体参数为用户提供了解决方案选择时必要信息,同时它们也是设计精馏设备时不可或缺的手段。基于以上详尽信息,可以更准确地预测并优化操作条件以满足各种精馏需求。

作为一种先进技术,金属丝网波纹填料展现出了以下优点:

高理论板数意味着更大的通量能力和较低的压力损失,为大规模生产提供支持。

负荷弹性的好处使得设备可以灵活适应不同的工作负载,无需担心极限负荷问题,即使是在较低负荷下仍能保持良好的性能水平。

操作灵活性强,便于实施各种调整以达到最佳运行状态,不会因为操作上的微小差异而导致严重后果发生。

放大效应控制良好,即便是在实际应用中可能出现的小误差,也不会引发系统性的错误或故障风险增加,对于需要高度纯净产品生产的人们尤为重要。

总结来说,metallic mesh wave filling material is a highly efficient and widely used type of filling material, with its unique structure and performance characteristics making it an ideal choice for various applications in the field of vacuum distillation.

Its main advantages include:

High theoretical plate number, resulting in high throughput capacity and low pressure drop.

Good load flexibility, allowing for smooth operation under varying loads without reaching lower limit values.

Operational elasticity ensures that small variations in operating conditions do not significantly impact system performance.

Controlled magnification effects minimize potential errors or faults during actual use.

These features make metallic mesh wave filling materials particularly suitable for demanding vacuum distillation applications involving difficult-to-separate mixtures, heat-sensitive substances, and the production of high-purity products.

The three models available are:

AX-250: Suitable for precise distillation processes requiring high strength but relatively fewer theoretical plates.

BX-500: Ideal for vacuum distillations at pressures below 7 KPa, especially when dealing with sensitive or difficult-to-separate substances.

CY-700: This model is best suited for separating isotopic mixtures or homogeneous mixtures with different structures.

By understanding these specifications and benefits, users can make informed decisions about which type of metallic mesh wave filling material to choose based on their specific needs and requirements.

Metallic mesh wave filling materials offer a powerful solution to many challenges faced by industries involved in precision engineering, chemical processing, petroleum refining as well as other sectors where efficiency matters most.

Their ability to handle complex separations while maintaining purity levels makes them invaluable assets within various industries worldwide.